MIC 12-1 Normal Pressure Can Filling Machine (1000-2000CPH)

Introduction to the MIC 12-1 Normal Pressure Can Filling Machine (1000-2000CPH)

At Jiangsu Mic Machinery, we pride ourselves on delivering high-quality, innovative machinery solutions for the beverage industry. With years of expertise and a commitment to excellence, we specialize in providing equipment that enhances production efficiency and product quality. One of our flagship products, the MIC 12-1 Normal Pressure Can Filling Machine, exemplifies our dedication to precision and reliability. This machine is designed specifically for filling non-carbonated beverages in aluminum cans, including water, juice, and tea, making it an essential addition to any production line.

Our goal is to offer equipment that addresses the unique needs of the beverage industry, ensuring that businesses can maintain consistent production while improving operational efficiency. The MIC 12-1 Normal Pressure Can Filling Machine is ideal for companies looking to automate their filling processes and reduce production costs while maintaining high-quality standards.

|

|

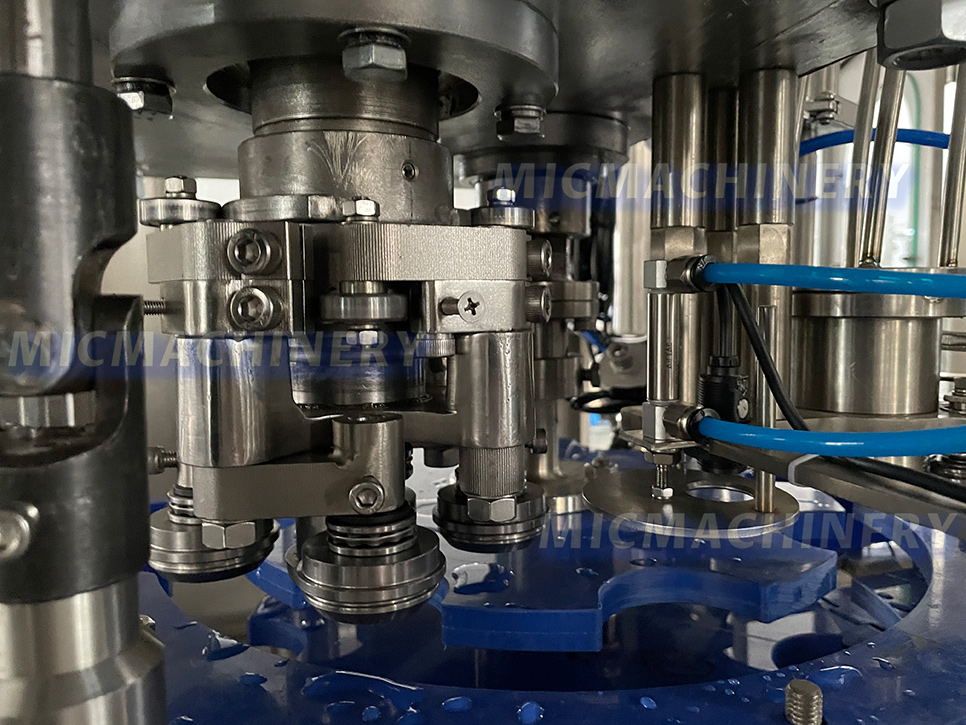

Aluminum can seaming system The aluminum can seaming system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle of the Can Filling Machine

The MIC 12-1 Normal Pressure Can Filling Machine operates based on a normal pressure filling principle, which is ideal for non-carbonated liquids. In this process, the liquid is drawn into the can filling machine and transferred into the can under normal atmospheric pressure, ensuring that no carbonation is lost in the process. This system is ideal for beverages that do not require pressurized filling, such as still water, fruit juices, and iced teas.

The filling valve used in the aluminum can filling machine is a key component, designed to deliver accurate and consistent fills. The valve operates by controlling the flow of liquid into the can, ensuring that each can is filled to the exact level, minimizing product wastage. The design of the automatic can filling machine also includes anti-drip features, preventing spillage and ensuring a clean and efficient filling process.

The machine is fully automated, equipped with a user-friendly interface that allows operators to monitor and control the entire filling process. It is capable of handling a variety of can sizes, from smaller 250ml cans to larger 500ml or 1L cans, making it a versatile solution for businesses that require flexibility in their production lines.

Advantages of the MIC 12-1 Normal Pressure Can Filling Machine

1、High-Speed Performance

The MIC 12-1 Normal Pressure Can Filling Machine operates at speeds ranging from 1000 to 2000 cans per hour (CPH), allowing for a high output while maintaining excellent filling precision. This high-speed capability makes it perfect for medium-scale production lines, helping businesses keep up with demand without compromising quality or efficiency.

2、Precise and Consistent Filling

One of the standout features of this can filling machine is its ability to deliver precise fills with minimal variation. The advanced filling technology ensures that each can receives the correct amount of liquid, which reduces product waste and improves overall yield. The machine’s high accuracy is particularly important for industries where product consistency and quality are key, such as juice and bottled water production.

3、Versatility for Different Can Sizes

The aluminum can filling machine is highly adaptable, able to accommodate different can sizes without requiring significant adjustments or downtime. Whether you are filling smaller cans (e.g., 250ml) or larger cans (e.g., 1L), the automatic can filling machine ensures smooth operation across all product formats. This flexibility makes it a valuable asset for businesses that need to switch between different product offerings.

4、Reduced Product Loss and Waste

The machine’s precision and controlled filling system help minimize overfilling, which can result in product loss and contamination. Additionally, the design of the MIC 12-1 Normal Pressure Can Filling Machine reduces foam formation, which is a common issue when filling carbonated beverages. As a result, the machine optimizes filling efficiency, ensuring that businesses maximize their production yield while reducing waste.

5、Durability and Low Maintenance

Built with high-quality stainless steel and other durable materials, the MIC 12-1 Normal Pressure Can Filling Machine is designed to withstand continuous operation in high-volume environments. The robust construction minimizes wear and tear, reducing the need for frequent maintenance. Additionally, the machine’s parts are designed for easy cleaning and maintenance, ensuring minimal downtime.

6、Automation for Increased Efficiency

As an automatic can filling machine, the MIC 12-1 features fully automated processes that help reduce the need for manual labor, which can increase productivity and decrease the risk of human error. The machine also includes advanced monitoring systems to track the filling process, ensuring high standards are maintained throughout production.

7、Cost-Effective Solution

The efficiency of the MIC 12-1 Normal Pressure Can Filling Machine translates into lower production costs over time. By optimizing the filling process, reducing waste, and minimizing maintenance needs, the machine offers a cost-effective solution that helps businesses maintain profitability in a competitive market.

8、User-Friendly Operation

The automatic can filling machine features an intuitive control panel that makes operation easy for technicians and operators, even with minimal training. With real-time monitoring, fault detection, and automated adjustments, the machine streamlines the filling process, ensuring that operators can focus on maximizing production without worrying about technical difficulties.

Conclusion

In conclusion, the MIC 12-1 Normal Pressure Can Filling Machine offers a reliable, efficient, and cost-effective solution for businesses looking to automate their non-carbonated beverage production. With its precise filling technology, high-speed operation, and versatility, it is an essential tool for companies seeking to improve operational efficiency while maintaining product quality. At Jiangsu Mic Machinery, we are committed to providing advanced solutions that meet the ever-evolving needs of the beverage industry. The MIC 12-1 Normal Pressure Can Filling Machine exemplifies our commitment to excellence, offering businesses the tools they need to succeed in today’s competitive market.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |