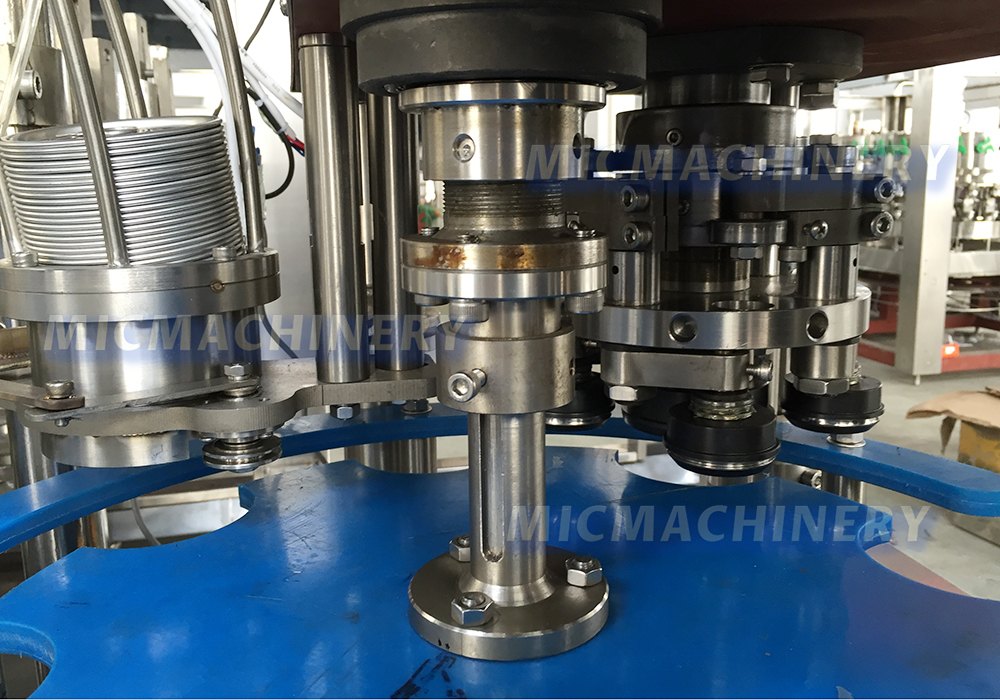

The 18-1 isobaric counter pressure filling system from “MIC” ensures a smooth, foam-free filling process—provided the beer remains below 40°F. Designed to maintain a standard 1.27 cm headspace as required by can manufacturers, it effectively accounts for product expansion and temperature fluctuations during transit. This system minimizes dissolved oxygen (DO) levels in the can, preserving beverage quality. Built with food-grade 304 stainless steel and finished with high-precision polishing, it offers superior hygiene and durability. A CIP connector can also be integrated based on customer needs, ensuring convenient and thorough internal cleaning.

MIC 18-1 Isobaric Pressure Can Filler Machine (1500-2500CPH)

Introduction to the MIC 18-1 Isobaric Pressure Can Filler Machine (1500-2500CPH)

At Jiangsu Mic Machinery, we specialize in providing advanced filling solutions for the beverage industry, combining high performance with reliability. Our MIC 18-1 Isobaric Pressure Can Filler Machine is designed to meet the high demands of carbonated beverage production. Whether you are filling soda, beer, or sparkling water, this can filling equipment ensures high-speed, precise, and consistent filling. With a filling capacity of 1500-2500 cans per hour, it provides an efficient solution for medium-scale production lines.

|

|

Isobaric pressure / counter pressure filling system

|

|

Can filling seaming machine lid feed system

The lid feed system in a can filling seaming machine is responsible for automatically supplying lids to the cans during the sealing process. It ensures a smooth and continuous flo w of lids, preventing delays and maintaining production efficiency. The system typically uses a conveyor or vibratory feeder to align and position lids correctly before they are placed on the filled cans. This automated process reduces the risk of contamination, improves the consistency of the seal, and speeds up the overall canning operation. The lid feed system is essential for ensuring that each can is securely sealed, maintaining product quality and preventing leakage.

|

|

Working Principle of the Can Filling Machine

The MIC 18-1 Isobaric Pressure Can Filler Machine operates on the isobaric filling principle, which is specifically designed for carbonated beverages. In this process, the pressure inside the can is balanced with the pressure in the filling tank to prevent foam loss and preserve carbonation. This is achieved by filling the can while maintaining equal pressure, ensuring that the liquid flows smoothly without disturbing the carbonation level.

The system starts by positioning the empty can under the filling valve. The can filler machine then fills the can from the bottom upward, using a specially designed valve that allows for smooth, controlled liquid flow. The pressure is adjusted to match the can’s internal pressure, ensuring that no foam or carbonation is lost during the process.

The can filling equipment is also equipped with advanced overflow and anti-drip mechanisms, ensuring that no liquid is wasted during the filling process. This results in high accuracy in filling volumes and minimizes product loss, making it highly efficient for large-scale production lines.

Advantages of the Can Filling Machine

1、Enhanced Filling Precision

The isobaric pressure filling method used in this can filling machine ensures that each can is filled to the exact volume, maintaining high consistency across all cans. The design of the filling valve prevents overfilling and ensures minimal wastage of the beverage.

2、High-Speed Production

The MIC 18-1 Isobaric Pressure Can Filler Machine offers a high-speed filling capacity of 1500-2500 cans per hour, making it ideal for medium to large-scale beverage producers. The efficient operation of the can filling equipment ensures continuous, uninterrupted production, even during peak demand periods.

3、Maintains Carbonation

One of the key advantages of this can filler machine is its ability to preserve carbonation levels, making it perfect for carbonated beverages. The precise isobaric filling process ensures that the beverage’s effervescence is maintained throughout the filling cycle, resulting in a superior product.

4、Durable and Low Maintenance

Built with high-quality materials, this can filling machine is designed for durability and longevity. The sturdy construction minimizes wear and tear, reducing the need for frequent maintenance and lowering the total cost of ownership. Its simple design and modular components also ensure easy access for cleaning and servicing.

5、Versatile and Flexible

The can filling equipment is highly versatile, capable of handling a variety of can sizes. Whether you are working with smaller 250ml cans or larger 500ml cans, the machine can be easily adjusted to accommodate different formats without significant downtime.

6、Automation for Increased Efficiency

This can filling machine is fully automated, reducing the need for manual intervention and allowing for more streamlined production. Operators can easily monitor the entire filling process via a user-friendly control panel, which offers real-time data on filling speeds, liquid levels, and machine status.

7、Cost-Effective Solution

By optimizing the filling process and minimizing waste, the MIC 18-1 Isobaric Pressure Can Filler Machine helps reduce production costs. Its high efficiency, combined with low maintenance needs, offers a cost-effective solution for businesses looking to improve their beverage filling operations.

8、Eco-Friendly Design

The machine's energy-efficient design and minimal product waste make it an environmentally friendly choice. The isobaric pressure system ensures that no liquid is wasted during the filling process, which not only helps businesses save on raw materials but also reduces environmental impact.

Conclusion

In conclusion, the MIC 18-1 Isobaric Pressure Can Filler Machine provides an efficient, reliable, and cost-effective solution for filling carbonated beverages at high speeds. Whether you are filling beer, soda, or sparkling water, this can filler machine is designed to meet the needs of modern beverage production lines. With its advanced technology, high-speed performance, and precise filling capabilities, it is an essential tool for any business looking to optimize its production process and maintain the highest quality standards.

At Jiangsu Mic Machinery, we are committed to providing innovative solutions that support the growth of the beverage industry. The MIC 18-1 Isobaric Pressure Can Filler Machine is just one example of our dedication to helping businesses succeed with state-of-the-art filling technology.

MIC 18-1 Parameters

| Power | 1.5Kw |

| Filling heads | 18piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2500CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1900*1300*1950mm |

| Weight | 2100Kg |

More Model and Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1000-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

Name |

Brand |

|

Buttons |

Schneider (France) |

|

Touch screen |

Siemens (Optional) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Optional) |

|

Frequency changer |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |

RELATED PRODUCTS

MIC 12-1 Isobaric Pressure Can Filler (1000-2000CPH)

MIC 12-1 Normal Pressure Can Filling Machine (1000-2000CPH)

MIC 18-1 Isobaric Pressure Can Filler Machine (1500-2500CPH)