MIC Manual Can Filling and Seaming Machine (8 cans per minute)

Company Introduction

Jiangsu Mic Machinery is a trusted manufacturer specializing in high-quality can filling solutions. With years of experience in the beverage industry, we deliver advanced equipment designed for superior performance and reliability. Our can filling and seaming machine lineup, including the aluminium can filling machine, reflects our commitment to innovation and precision. We are dedicated to providing businesses with the tools they need to enhance production efficiency and product quality. At Jiangsu Mic Machinery, we continuously strive to meet the evolving needs of beverage manufacturers with state-of-the-art technology and exceptional customer support.

|

|

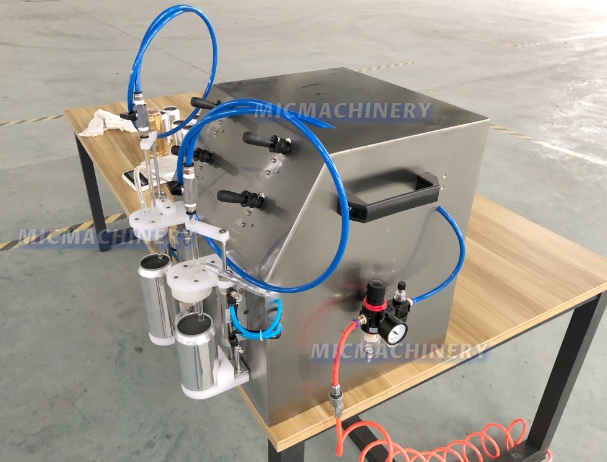

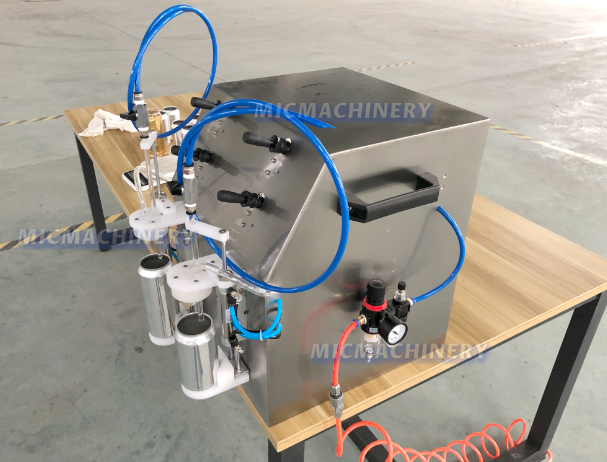

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can. |

|

Control Button |

|

|

|

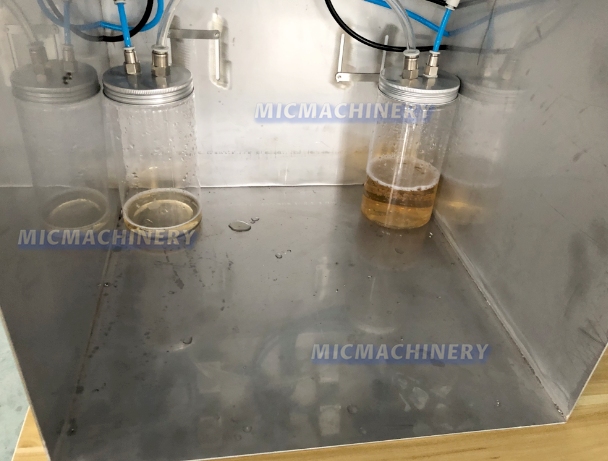

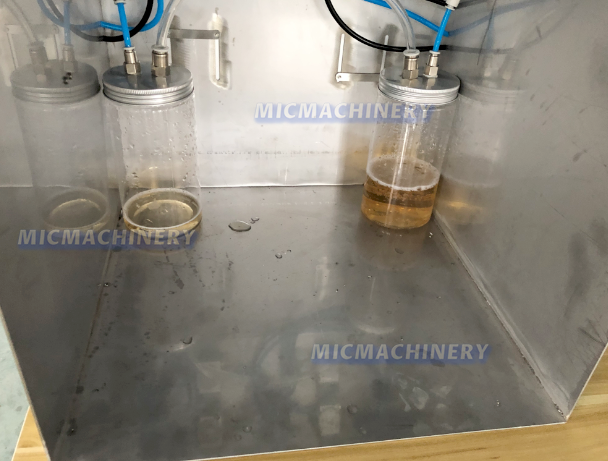

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Working Principle of Can Filling Machine

The MIC Manual can filling and seaming machine is designed for small-scale, high-quality filling operations. This machine is ideal for businesses with lower production requirements, filling up to 8 cans per minute. The filling process begins with the can filling machine feeding an empty can onto the platform. The machine uses a manual control system, where operators carefully fill the cans with liquid, ensuring accuracy and precision.

Once the cans are filled, they are automatically transferred to the seaming station, where the can filling and seaming machine uses a reliable and durable sealing mechanism to attach the lids. The seaming system is engineered for airtight sealing, preventing leakage and preserving the quality of the beverage inside. The aluminium can filling machine ensures that each can is filled to the correct volume, maintaining consistency and minimizing waste.

This manual system provides operators with greater control over the filling process while also allowing for flexibility in the types of liquids that can be filled, including carbonated and non-carbonated beverages.

Advantages of Can Filling Machine

1、Simple Operation

The MIC Manual can filling and seaming machine is straightforward to use, with a manual operation system that requires minimal technical expertise. Operators can quickly learn the machine’s functions, allowing for a faster startup and less downtime.

2、Precision and Accuracy

The can filling machine offers highly accurate filling, ensuring that each can is filled to the correct level. This precision minimizes overfilling and waste, which is especially important for small-scale operations looking to optimize resources.

3、Cost-Effective for Small Production

With its low filling capacity of 8 cans per minute, the aluminium can filling machine is ideal for small-scale businesses or testing new products without the need for large-scale machinery. It offers an affordable and efficient solution for businesses with lower production needs.

4、Versatility in Filling Liquids

The can filling and seaming machine is highly adaptable, making it suitable for a variety of beverages. Whether you’re filling soft drinks, juices, or other liquids, this machine can handle different types of beverages with ease.

5、Compact Design

The compact design of the can filling machine makes it perfect for small production spaces. Its compact footprint allows it to fit into areas where larger machines would be impractical, offering flexibility for businesses with limited space.

6、Durability and Reliability

Built with high-quality materials, the aluminium can filling machine ensures long-term durability and minimal maintenance. It is engineered for continuous use, providing a reliable solution for small-scale filling operations.

7、High-Quality Sealing

The can filling and seaming machine ensures that each can is tightly sealed with an airtight lid, preventing leaks and preserving the beverage's freshness. The machine's seaming system is designed to handle various types of can lids, ensuring secure closure every time.

8、User-Friendly Interface

The machine features a manual control interface that is easy to operate. With clear instructions and a simple setup, even operators with limited experience can quickly master the machine and maintain efficient production.

9、Flexibility in Production

The manual operation system offers flexibility, making it easy for operators to adjust the filling process based on the specific needs of the beverage. This is particularly beneficial for businesses that produce a range of different products and require variable filling amounts.

10、Low Maintenance Requirements

Thanks to its sturdy construction and straightforward design, the MIC Manual can filling and seaming machine requires minimal maintenance, which helps reduce operational costs over time. Routine maintenance is easy to perform, ensuring a hassle-free experience for operators.

In conclusion, the MIC Manual can filling and seaming machine provides a cost-effective, reliable, and precise solution for small-scale can filling operations. Its user-friendly design, versatility, and consistent performance make it an excellent choice for businesses looking to streamline their production processes without the need for large, complex equipment. Whether you’re just starting out or need a simple, efficient filling system, this machine meets the demands of high-quality beverage production.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ML and 550 ML |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand | |

| Buttons | Schneider (France) | |

| Touch screen | Siemens (Optional) | |

| AC Contactor | Schneider (France) | |

| PLC | Mitsubishi (Japan) / Siemens (Optional) | |

| Frequency changer | Schneider (France) | |

| Air cylinder | AirTAC (China) / FESTO (Optional) | |

| Solenoid valve | AirTAC (China) / FESTO (Optional) | |

| Relay | Omron (Japan) / Schneider (France) | |

| photoelectric sensor | Autonics (Korea) / Omron (Optional) | |

| Proximity switch | Autonics / Omron (Optional) | |