MIC Semi-Automatic Can Sealing Machine (15CPM)

MIC Semi-Automatic Can Sealing Machine

Company Introduction

Mic Machinery is a leading manufacturer specializing in innovative packaging solutions for the beverage industry. With a strong commitment to quality and technology, we provide reliable equipment designed to enhance production efficiency. Our products include advanced filling and sealing systems, such as the MIC Semi-Automatic Can Sealing Machine, which is well-suited for various beverage packaging needs.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

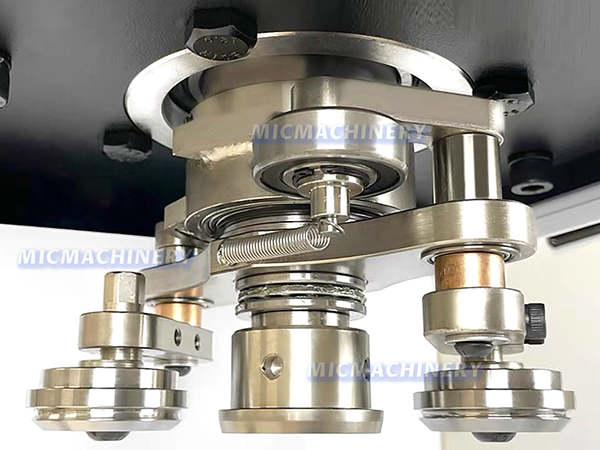

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to bottles, jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

1)The semi-automatic can sealing machine operates through a straightforward and efficient process:

2)The operator manually places the filled aluminum can (usually filled by an aluminum can filling machine) onto the machine platform.

3)A lid is positioned on the can before sealing.

4)Activating the machine engages the sealing head, which presses and rolls the lid edge tightly onto the can body, creating an airtight seal.

5)Once sealing is complete, the can is lowered, ready for removal.

Features and Advantages

▪ Reliable Sealing Quality: Ensures airtight and leak-proof seals to maintain product freshness.

▪ User-Friendly Operation: Simple controls and semi-automatic functionality reduce operator fatigue.

▪ Durable Construction: Made with high-quality materials for long service life and easy cleaning.

▪ Compact Design: Saves factory floor space while integrating well with existing production lines.

▪ Versatile Compatibility: Easily pairs with various aluminum can filling machines for seamless production.

Applications

The can sealer is ideal for carbonated drinks, juices, energy drinks, and other beverages packaged in aluminum cans. It is widely used in small and medium-sized beverage factories, research and development labs, and pilot production lines. Its flexibility makes it an excellent choice for businesses aiming to expand or optimize their packaging processes.

Conclusion

The MIC Semi-Automatic Can Sealing Machine offers a dependable, cost-effective solution for quality can sealing. Combined with an aluminum can filling machine, it forms a complete canning system that enhances production efficiency and product safety. Mic Machinery remains committed to delivering cutting-edge technology to support your beverage packaging needs.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |