Showing 19–27 of 66 results

Blow Drying Equipment

Blow drying equipment is designed to provide fast and efficient drying solutions for various industries. It uses high-speed airflow to reduce drying times, improve productivity, and ensure consistent results for large-scale operations.

Learn more

Tunnel pasteurization equipment

Tunnel pasteurization equipment ensures the safe and efficient thermal processing of beverages by gradually heating and cooling products in a controlled environment, extending shelf life while preserving quality and flavor.

Learn more

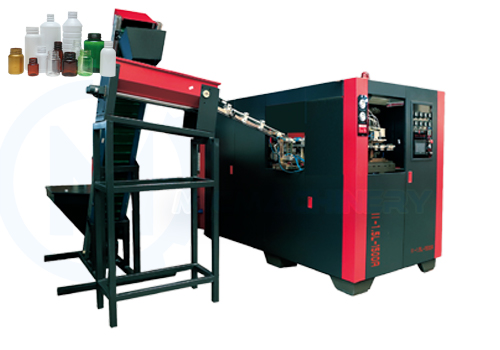

MIC-II-1.5L-1500A Bottle Blowing Machine

The bottle blowing machines apply to below 1.5L bottles for mineral water, beverage, condiment cosmetic and pharmaceutical, etc.

Learn more

Single-effect External Circulation Vacuum Concentrator

The equipment is applicable for the concentration and recovery of industrial organic solvent (such as alcohol) of traditional Chinese medicine, western medicine, glucose, starch sugar, oral liquid, chemical industry, food, monosodium glutamate and dairy products. lt can be used in the low temperature vacuum concentration of heat sensitive substances with srnall batches and large varieties.

Learn more

MIC WYD-300 Nitrogen Dosing Equipment

The MIC WYD-300 Nitrogen Dosing Equipment delivers precise nitrogen infusion for packaging, enhancing product quality and shelf life. With advanced automation and reliable performance, it optimizes processes in industries like food, beverage, and pharmaceuticals.

Learn more

MIC WYD-600 Industrial nitrogen dosing

The MIC WYD-600 Industrial Nitrogen Dosing system ensures precise nitrogen infusion for packaging, preserving freshness and stability. With advanced automation and high efficiency, it enhances production in food, beverage, and pharmaceutical industries.

Learn more

Pasteurisation Machine

The Pasteurisation Machine ensures effective heat treatment for beverages and dairy products, eliminating harmful bacteria while preserving taste, texture, and nutritional value, extending shelf life, and meeting industry standards.

Learn more

MIC-II-2.5L-1500A PET Bottle Blowing Machine

The bottle blowing machines apply to below 2.5L bottles for mineral water, beverage, condiment cosmetic and pharmaceutical, etc.

Learn more

Double Effect Energy Saving Concentrator

The concentrator is applicable for concentration of liquid materials for traditional Chinese medicine, western medicines, glucose, starch, monosodium lutamate, dairy foods and chemical industry, especially ideal for low temperature vacuum concentration of heat sensitive substances.

Learn more