Showing 37–45 of 66 results

Ball Type Concentrating Tank

The roundness concentration tank, consisting of main body, condensator, gas-liquid separator and liquid receiving, barrel, serves to concentrate distil the material liquid and reclaim organic menstruum in the pharmacy, foodstuff and chemistry. The concentration under reduced pressure brings short time of concentration and prevent the destruction of the effective content in the thermat sensitive material.The fact that the part in contact with the material is made with stainless steel brings qualified anti-corrosion performance, meeting with the GMP standard.

Learn more

Aseptic Liquid Nitrogen Dosing Equipment

Our Aseptic Liquid Nitrogen Dosing Equipment ensures precise nitrogen infusion while maintaining sterile conditions. Designed for food, beverage, and pharmaceutical packaging, it enhances product stability, freshness, and shelf life with advanced automation and high efficiency.

Learn more

Commercial Pasteurizer Machine Price

The Commercial Pasteurizer Machine provides reliable heat treatment for beverages and dairy, eliminating bacteria while preserving taste, texture, and nutritional value, ensuring quality, safety, and extended shelf life.

Learn more

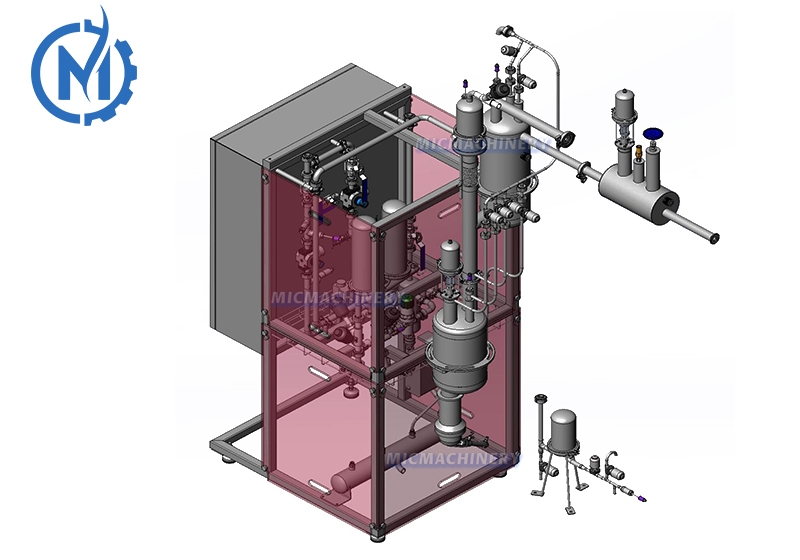

Multifunctional Alcohol Recovery Concentrator

This equipment is suitable for concentrating traditional Chinese medicine and alcohol precipitation solutions and recovering alcohol.

Learn more

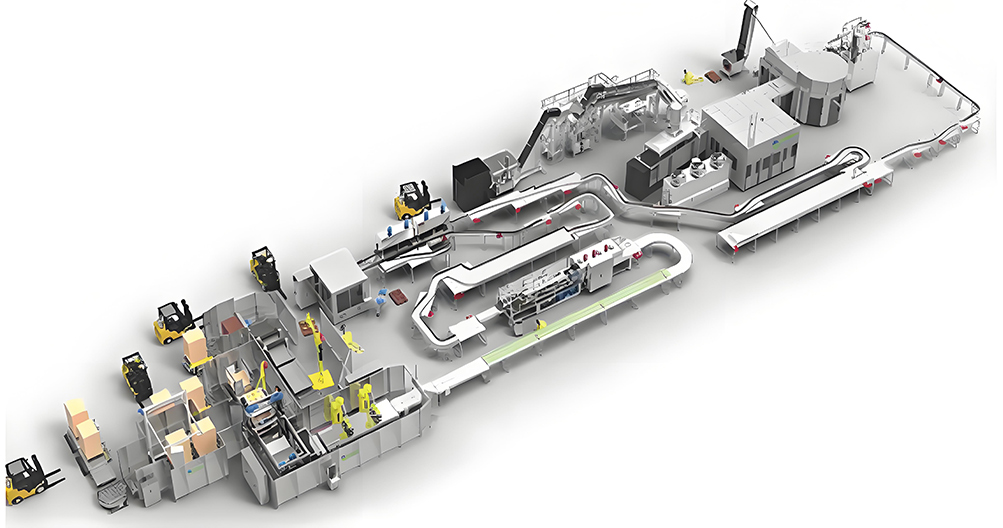

MIC-VI-0.8L-9000A Bottle Blow Molding Machine

The bottle blowing machine is suitable for bottles below 0.8 L used for mineral water, beverages, condiments, edible oil, cosmetics, and pharmaceutical products, meeting the diverse bottle sample requirements of different industries.

Learn more

Pasteurizer Machine for Sale

Our Pasteurizer Machine for Sale offers efficient heat treatment for beverages and dairy, eliminating bacteria while preserving flavor, texture, and nutrients, ensuring high-quality production and extended shelf life.

Learn more

MIC-VII-R-12000A Plastic Bottle Blowing Machine

The MIC automatic energy-saving rotating machine uses a continuous rotation feeding structure for preforms, reducing the space required and eliminating the need to manually turn them, making operation simple. Its continuous heating system maintains a 50 mm distance between preforms, providing intensive and uniform heating, saving lamp space, greatly improving heating efficiency, and reducing energy consumption by up to 25–30%.

Learn more

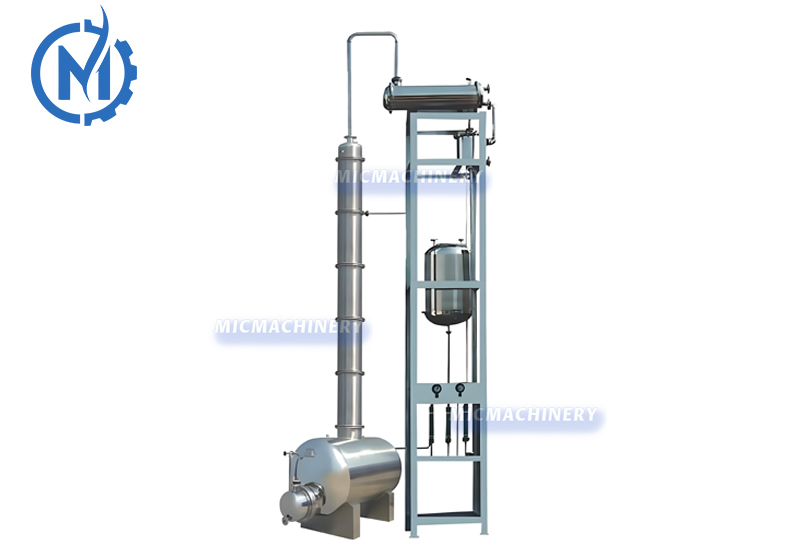

Alcohol Recovery Tower

This equipment is suitable for the percolation operation of traditional Chinese medicine, plant, animal, food, chemical and other industries. In addition to frankincense,rosin, aloe and other non-tissue medicinal materials due to solvent softening into a group, will block the pores so that the solvent can not evenly through the medicinal materials, and should not be used for percolation, other medicinal materials can be extracted by this method.

Learn more

Single Effect Falling Film Evaporator

This equipment adopts falling film evaporation. It is mainly composed of evaporator, separator, condenser and other parts. It is widely used in concentration and dehydration in food, biology, pharmaceutical, organic solvent, chemical and other industries. The control mode is manual control and automatic control.

Learn more